Hubei Craun Technology Equipment Co., Ltd.

Hubei Craun Technology Equipment Co., Ltd (abbreviated as Craun Tec.), with the registered capital of 10 million RMB and 25000㎡ factory ground, is located in High Tech. industrial park of Xian Ning, Hubei province, which is 100 Kilometers away from Wuhan. The HQ is divided into two parts, mechanical precision processing factory and equipment manufacturing factory. We have more than 100 sets professional precision processing center, inspection equipment, heavy manufacturing equipment and complete environmental protection treatment equipment. Craun Tec. focuses on the technology R&D on the field of solid-liquid separation, and has the independent R&D and fast & efficient system solution capabilities, it is a global professional manufacturer integrating system design, technology R&D, production and sales and after-sales service.

Service Fields:

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

Environmental governance (river / port dredging, remediation of contaminated soil, sorting of construction waste, comprehensive disposal of municipal waste, reuse of sand washing sewage, etc.)

Industrial pollution (tailing slurry treatment, industrial waste-water treatment and reuse, waste-water treatment for coal washing, etc.).

Enterprise spirit:Concentration, Innovation, Deploitation, Cooperation, Serve every customer with heart attentively!

Quality Management

We adopt a complete electronic enterprise production management system, production is strictly in accordance with the API standard, we also have the traceable electronic card for single process. Adhering to the management principle of downstream management and upstream management, we pursue zero defect system delivery.

Vertical system management, continuous simplifying the production processes, improving the efficiency on production & problem solving, taking the fully responsibility for the products we produced.

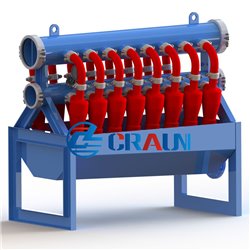

avail Capacity (m³/h): 120/240, 120/240/360, 240/360

avail Cyclone Qty: 8,12, 12,16, 8,12,16

avail Working Pressure (Mpa): 0.25-0.45

avail Capacity (m³/h): 120/240 , 120/240/360 , 240/360

avail Desander Cyclone (Qty): 1,2, 2,3, 1,2,3

avail Working Pressure (Mpa): 0.25-0.45

avail Diameter (mm): 450, 360, 530

avail Length (m): 1105, 1540, 1270, 2120

avail Capacity (m³/h): ≤50, ≤60, ≤40, ≤80

avail Bowl Rotary Speed (rpm): 1800, 2200, 0-3200, 0-2800

avail G-Force (G): 815, 1220, 2062, 2327

avail Separation Point (µm): 5-7, 2-5

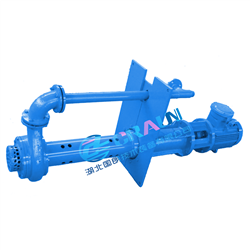

avail Flow (m³/h) : 30, 40, 60, 80 to 270

avail Lift (m): 10, 18, 20, 30, 25

avail Power (kW): 4, 5.5, 7.5, 11, 22, 30, 37, 45

avail Outlet Sizes (mm): DN50, DN80, DN100, DN150

avail Flow (m³/h) : 100, 150

avail Lift (m): 25, 32

avail Power (kW): 37, 55

avail Rotating Speed (rpm): 1900, 2200

avail Weight (kg): 830, 930

avail Flow (m³/h) : 12, 20, 30, 45, 55, 80

avail Pressure (Mpa): 0.6, 1.2

avail Motor Power (kW) : 4, 5.5, 7.5, 11, 15, 18.5, 22, 30

avail Max Speed (rpm): 400, 720, 960

avail Inlet Sizes (mm/inch): DN80/3 , DN100/4 to DN250/10

avail Outlet Sizes (mm/inch): DN65/2.5" , DN80/3" to DN200/8"

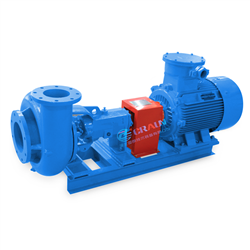

avail Flow (m³/h) : 23, 45, 55, 90, 120 to 320

avail Lift (m): 25, 28, 29, 30, 35

avail Motor Power (kW) : 7.5, 11, 15, 22 to 75

avail Rotating Speed (rpm): 1450, 1750

avail Impeller Diameter (inch): 9.5, 10, 11, 12, 13, 14