iCWD - intelligent Circulation Sub // Outer Diameter 5" Operation Modes: Bypass, Dual Flow (Hole Cleaning), Isolation, Home (Default Drilling) Design/Feature Activation System: Agile Activation; 5 min (using RPM downlink); 10 min (using flow downlink); 10 min (using pressure downlin Type Slim Tool Bore Large open bore

Supplier MIT Technologies

Product Technical Configuration

| Outer Diameter | 5" |

| Type | Slim Tool |

| Operation | Modes: Bypass, Dual Flow (Hole Cleaning), Isolation, Home (Default Drilling) |

| Design/Feature | Activation System: Agile Activation; 5 min (using RPM downlink); 10 min (using flow downlink); 10 min (using pressure downlin |

| Bore | Large open bore |

| Number of Cycles | 18 activation or more per run |

Application: Drilling operation

Product country of origin: Malaysia

Location of the product: Malaysia

Available: For Sale

Supplier reference: iCWD-5

Original manufacturer: MIT Technologies

Finalized quotes will be sent directly to the supplier

Description

Intellgent Circulation While Drilling tool (iCWD), is a multi cycle circulating sub that does not require a drop ball, dart or token to operate.

It does not even require to break a connection or drop slips to activate.

iCWD is an intelligent circulating sub enabling the driller to treat losses, place cement plugs or improve hole cleaning without the need to pull out of hole, saving expensive rig time.

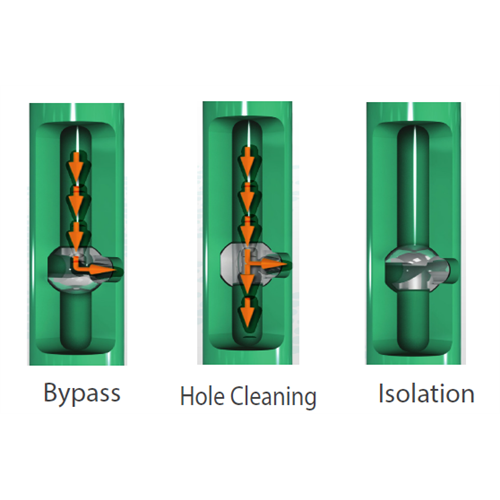

iCWD has four modes of operation namely default drilling, bypass, dual flow for hole cleaning and isolation modes.

iCWD is operated from surface using the patented Agile (R) activation system through a downlink of RPM, or change of flow rate.

iCWD can even operate when flow is not possible for example in situation such as packed off hole or plugged bit nozzle, where in such a case the iCWD can be operated through a timed sequence of pressure to the drilling string.

iCWD can be operated from any mode, in any seqence, practically any number of times, and through any of the Agile activation mechanism in any order.

iCWD incorporates Smart Electronic and sensors which enables operators to run multiple tools in the same string spaced out as required with each independently controlled and activated into any desired mode.

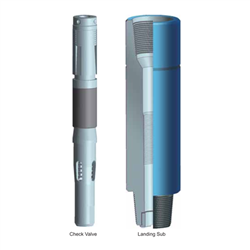

iCWD design is based on a remotely controlled 3-way ball valve for drilling systems and was jointly developed by MIT Technologies and Petronas.

Engineer-Less operation.

Automatic power up, and Driller Caddie activation assistance installed on one 2 certified wearable watch or Zone 2 certified mobile (provided with the tool). Sour environment. Special preparation will be required for H2S or CO2 services.

Mutiple iCWD can be placed in same drilling string, each activated independently, with No restriction on placement location of each iCWD tool.

iCWD can be installed anwhere in the drilling string. More than one tool can be placed spaced apart or stacked within the drilling string with no placement restrictions.

Agile activation sytem does not require mechancial access to the tool, hence can be placed below interrupted mud passage such as below LWD or below a ball activated tool or float valve.

Application:

1) Multiple tools: improved hole cleaning for extended reach wells where iCWD tools can be spaced apart. The one near well heel is activated to HC mode, then when pulled to vertical, the next deeper tool is activated to HC mode until vertical; When a tool is placed below BHA and there is risk of losses, another tool will be required above BHA.

Each iCWD tool can be activated independent of the other tool; Slim hole drilling below large casing: Annular velocity inside casing is limited by the flow rate within slim BHA.

In some cases, the slim LWD/MWD limits the flow rate and result in either drilling slowly or risking stuck pipe. To improve anular velocity within the higher casing area, a larger iCWD is placed within the drilling string such that when reaching the slim TD, the iCWD in side casing is above the casing shoe and can be activated separately into dual flow (Hole Cleaning) mode pumping more than the limit of BHA.

A second iCWD tool can be placed within the slim BHA for normal drilling risk mitigaioation with losses or stuck pipe.

2) Placement HPHT Fingerprint before drilling out shoe track where iCWD can be placed above motor and below LWD. Formation pressure while drilling applicaiton when mud motor is used, through placement of iCWD below FPWD and above motor, allowing ciruclation while bypassing motor preventing motor from spining and save the FPWD probe from vibration and unsetting.

Large open bore for fishing or ball activated tool below. Uninterrupted tool bore enables user to run ball activated tool below iCWD such as coring or under reamer.

Allows for fishing radioactive source or running free point tool through the iCWD Modes of Operation:

Bypass mode: All fluid pumped from surface are directed to side port.

Application: Placement of LCM, Cement, or any other chemical; Wellhead Jetting; improved circulation after coring;

Dual Flow (Hole Cleaning) mode: Fluid pumped from surface is split into two passage, a portion is circulated though BHA below iCWD and another portion is circulated through side port. Flow split is based on BHA configuration. Split % can be calculated for each run based on BHA hydraulics

Application: Improve annular velocity, Improve hole cleaning, autofill. Special application particularly for slim holes where BHA flow limitation affect hole cleaning particulalry in the larger casing side above the slim section.

Adding iCWD above BHA can increase total flow rate through providing additional passage for additional flow through the sie port, while maintaing original flw rate through BHA within required boundaries.

Isolation Mode: In this mode, the iCWD valve is operated such that it isolate the inner fluid passage above iCWD to surface from downhole condition. This mode could be beneficial.

Application: Well control, Running inhole with dry pipe Home (Default Drilling) mode: in this mode, the iCWD valve is positioned such that side port is closed, while 100% of fluid pumped from surface goes down through iCWD to the string below. In otherwords, the tool a is as a pup joint.

Application: Drilling

Brand

iCWD created by MIT Technologies is an intelligent circulating sub enabling the driller to treat losses, place cement plugs or improve hole cleaning without the need to pull out of hole, saving expensive rig time.

Related Product Variants

| Product Name | Configuration | |

|---|---|---|

| iCWD - intelligent Circulation Sub | Outer Diameter | 5" |

| Type | Slim Tool | |

| Operation | Modes: Bypass, Dual Flow (Hole Cleaning), Isolation, Home (Default Drilling) | |

| Design/Feature | Activation System: Agile Activation; 5 min (using RPM downlink); 10 min (using flow downlink); 10 min (using pressure downlin | |

| Bore | Large open bore | |

| Number of Cycles | 18 activation or more per run | |

| iCWD - intelligent Circulation Sub | Outer Diameter | 7" |

| Type | Standard Tool Model 700 | |

| Operation | Modes: Bypass, Dual Flow (Hole Cleaning), Isolation, Home (Default Drilling) | |

| Design/Feature | Activation System: Agile Activation; 5 min (using RPM downlink); 10 min (using flow downlink); 10 min (using pressure downlin | |

| Bore | Large open bore | |

| Number of Cycles | 18 activation or more per run | |

| iCWD - intelligent Circulation Sub | Outer Diameter | 8 1/4" |

| Type | Large Size Tool Model 825 | |

| Operation | Modes: Bypass, Dual Flow (Hole Cleaning), Isolation, Home (Default Drilling) | |

| Design/Feature | Activation System: Agile Activation; 5 min (using RPM downlink); 10 min (using flow downlink); 10 min (using pressure downlin | |

| Bore | Large open bore | |

| Number of Cycles | 18 activation or more per run | |

Sourcing, Rentals & Services

Looking for specific tools, deals, services, rentals, manpower or any items not currently available on RIA marketplace?

Please send us your request for quotation and we will source accordingly.