Drilling Turbines / Downhole Mud Motors // Motor Size 245 mm / 9 5/8" Type Standard Hole Size 286-455 mm / 11 1/4"-17 1/2" Motor Type Vertical

Supplier PKT Turbo

Product Technical Configuration

| Type | Standard |

| Motor Size | 245 mm / 9 5/8" |

| Hole Size | 286-455 mm / 11 1/4"-17 1/2" |

| Motor Type | Vertical |

Product country of origin: UAE

Location of the product: UAE

Available: In Stock

Supplier reference: D200302A-1

Original manufacturer: PKT Turbo

Finalized quotes will be sent directly to the supplier

Description

Discover the efficiency of downhole drilling turbines, cutting-edge devices revolutionizing the oil and gas and geothermal industry. Downhole drilling turbines (turbodrills) are designed for optimal performance, enhancing drilling operations with precision and speed. Engineered to navigate challenging subsurface environments, these turbines ensure increased productivity and reduced operational costs. Explore the latest innovations in downhole drilling technology and streamline your drilling processes with our advanced turbines. Trust in our reliable solutions to boost your drilling capabilities and achieve unparalleled results. Learn more about how our downhole drilling turbines can elevate your operations to new heights.

Applications:

1. Oil and Gas drilling: Downhole mud motors, CTD Coiled Tubing Drilling, Descaling, Vertical, Deviated, Horizontal, HPHT high pressure high temperature.

2. Geothermal drilling: Downhole mud motors, all drilling applications such as HT high temperature including customized tool.

Advantages of drilling turbines compared to drilling mud motors (PDM positive displacement motors):

1. Increased Penetration Rates:

· Drilling turbines are known for their ability to provide higher penetration rates compared to drilling mud motors. This results in faster drilling progress, ultimately saving time and reducing operational costs.

2. Improved Energy Efficiency:

· Turbines often exhibit better energy efficiency, translating to a more effective conversion of hydraulic energy into mechanical energy. This efficiency can lead to reduced fuel consumption and overall operational expenses.

3. Enhanced Reliability:

· Drilling turbines are recognized for their robust design and reliability in challenging downhole conditions. Their streamlined construction reduces the likelihood of mechanical failures, contributing to increased operational uptime.

4. Precise Control and Steering:

· Turbines offer precise control and steering capabilities during drilling operations. This level of control allows for more accurate well placement, minimizing the risk of deviation and optimizing overall wellbore integrity.

5. Reduced Maintenance Requirements:

· Drilling turbines often have simpler designs with fewer moving parts compared to drilling mud motors. This simplicity can result in reduced maintenance requirements, leading to lower downtime and operational disruptions.

6. Versatility in Formation Types:

· Drilling turbines can demonstrate versatility in various geological formations. Their design allows for effective drilling in both soft and hard formations, providing adaptability to a wide range of drilling scenarios.

7. Cost-effectiveness:

· Due to their efficiency and reliability, drilling turbines can offer a cost-effective solution over the long term. The combination of faster drilling rates, reduced maintenance, and lower operational costs contributes to overall cost-effectiveness.

8. Minimized Environmental Impact:

· With their optimized energy efficiency and streamlined operation, drilling turbines may contribute to a reduced environmental impact compared to some traditional drilling methods. This aligns with the industry's growing emphasis on sustainability.

By considering these advantages, operators can make informed decisions when selecting drilling technologies based on their specific project requirements and goals.

Documentation

Brand

Petro-King Turbo FZCO (formally called TurboDynamics Pte Ltd) is a Dubai incorporated company dedicated to advancing turbodrill technology and the provision of related high-quality operational services to the Oil & Gas drilling industry. The company is incorporated at Dubai Airport Free Zone (DAFZA) since Nov 22nd, 2017. Previously it was a wholly owned subsidiary of Petro-king Oilfield Services Ltd who are listed on the Hong Kong stock exchange (2178).

From its inception in 2011 Petro-King Turbo FZCO (PKT Turbo), remit has been to design a turbodrill with a view to making it more powerful, efficient and user friendly both from an operational perspective and also from a manufacturing and maintenance standpoint, when compared to any other competitor turbodrill currently in the global market. This has been achieved primarily by having a core management team with over 100 years cumulative oilfield drilling experience within excess of 60 of those years specifically involved in all aspects of the global Turbodrilling business, from design, manufacturing, to sales and operations.

Our goal was and is simply to provide our customers with quality solutions and services, through continuous advancement of technology.

Following an intense R&D and manufacturing period TurboDynamics (Today’s called Petro-King Turbo FZCO) introduced their first turbodrills into the market in early 2013.

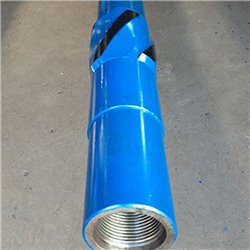

Turbodrill Principle

A turbodrill consists of multistage vane-type stator and rotor blades which converts the hydraulic energy (flow x pressure) of the drilling fluid into mechanical energy to drive a shaft and drill bit. A “stage” consists of one set of stator and rotor blades. The stators are stationary, locked to the turbine body, and deflect the flow of drilling fluid onto the rotors which are locked to the drive shaft. As the rotors are forced to turn, the drive shaft is also forced to turn, causing the bit to rotate.

Related Product Variants

| Product Name | Type | Motor Size | Hole Size | Motor Type |

|---|---|---|---|---|

| Drilling Turbines / Downhole Mud Motors | HTHP | 121 mm / 4 3/4" | 143-171 mm / 5 5/8"-6 3/4" | Vertical |

| Drilling Turbines / Downhole Mud Motors | Standard | 121 mm / 4 3/4" | 143-171 mm / 5 5/8"-6 3/4" | Directional |

| Drilling Turbines / Downhole Mud Motors | Standard | 121 mm / 4 3/4" | 143-171 mm / 5 5/8"-6 3/4" | Vertical |

| Drilling Turbines / Downhole Mud Motors | HTHP | 121 mm / 4 3/4" | 143-171 mm / 5 5/8"-6 3/4" | Directional |

| Drilling Turbines / Downhole Mud Motors | Standard | 172 mm / 6 3/4" | 194-251 mm / 7 5/8"-9 7/8" | Directional |

| Drilling Turbines / Downhole Mud Motors | HTHP | 172 mm / 6 3/4" | 194-251 mm / 7 5/8"-9 7/8" | Vertical |

| Drilling Turbines / Downhole Mud Motors | Standard | 172 mm / 6 3/4" | 194-251 mm / 7 5/8"-9 7/8" | Vertical |

| Drilling Turbines / Downhole Mud Motors | HTHP | 172 mm / 6 3/4" | 194-251 mm / 7 5/8"-9 7/8" | Directional |

| Drilling Turbines / Downhole Mud Motors | HTHP | 245 mm / 9 5/8" | 286-455 mm / 11 1/4"-17 1/2" | Vertical |

| Drilling Turbines / Downhole Mud Motors | Standard | 245 mm / 9 5/8" | 286-455 mm / 11 1/4"-17 1/2" | Directional |

| Drilling Turbines / Downhole Mud Motors | Standard | 245 mm / 9 5/8" | 286-455 mm / 11 1/4"-17 1/2" | Vertical |

| Drilling Turbines / Downhole Mud Motors | HTHP | 245 mm / 9 5/8" | 286-455 mm / 11 1/4"-17 1/2" | Directional |

| Drilling Turbines / Downhole Mud Motors | HTHP | 73mm / 2 7/8" | 83-102 mm / 3 1/4"-4" | Vertical |

| Drilling Turbines / Downhole Mud Motors | Standard | 73mm / 2 7/8" | 83-102 mm / 3 1/4"-4" | Directional |

| Drilling Turbines / Downhole Mud Motors | Standard | 73mm / 2 7/8" | 83-102 mm / 3 1/4"-4" | Vertical |

| Drilling Turbines / Downhole Mud Motors | HTHP | 73mm / 2 7/8" | 83-102 mm / 3 1/4"-4" | Directional |

Sourcing, Rentals & Services

Looking for specific tools, deals, services, rentals, manpower or any items not currently available on RIA marketplace?

Please send us your request for quotation and we will source accordingly.